Top angle brackets metal in China introduce,list main products and website if have

Angle brackets are vital components in construction and engineering projects, providing support and reinforcement for various structures. In China, there are numerous manufacturers that specialize in producing top-quality angle brackets made from metal. Some of the main products offered by these companies include L-shaped angle brackets, corner braces, shelf brackets, and heavy-duty angle brackets.

One of the leading manufacturers of metal angle brackets in China is Shandong Laoqiang Industry Co., Ltd. Their product range includes a wide variety of angle brackets made from high-quality steel and aluminum alloys. You can find more information about their products and services on their website www.lqindustry.com.

Another reputable company in China that offers metal angle brackets is Hangzhou Sako Hardware Co., Ltd. They specialize in producing custom-made angle brackets for specific project requirements, ensuring high precision and durability. You can visit their website at www.sakohardware.com for more details on their products and customization options.

Additionally, Dongguan Fengxing Hardware Co., Ltd is a trusted manufacturer of metal angle brackets in China, providing a diverse range of products suitable for different applications. They offer competitive prices and efficient delivery services for customers worldwide. You can find more information about their products on their website at www.fengxinghardware.com.

In conclusion, metal angle brackets are essential components in various industries, and China offers a wide range of manufacturers that specialize in producing top-quality angle brackets. Whether you are looking for standard-size angle brackets or custom-made designs, these companies can meet your specific requirements with their expertise and high-quality products.

Types of angle brackets metal

Angle brackets are commonly used in construction and fabrication to provide support or reinforcement in various structures. There are several types of metal angle brackets depending on the application and the required strength and durability.

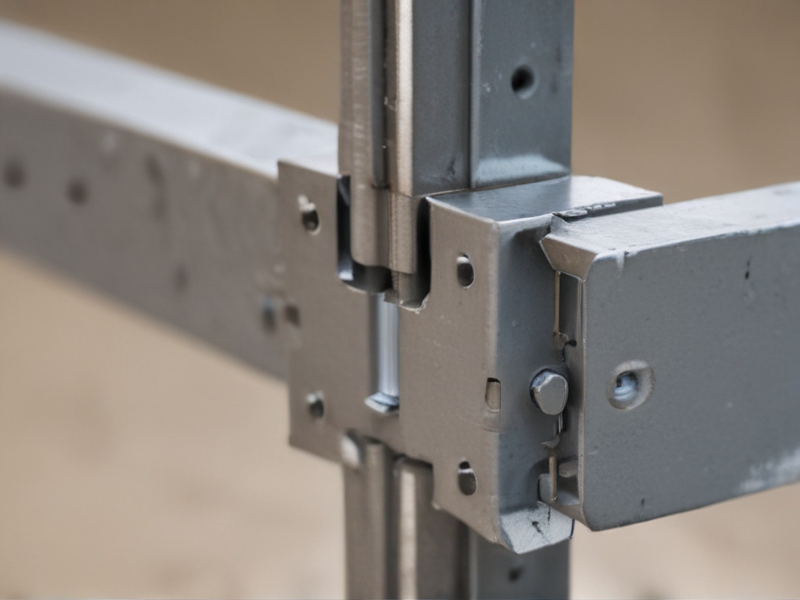

One of the most common types of metal angle brackets is the L-shaped bracket, which is typically used to connect two surfaces at a right angle. These brackets are often made from steel or aluminum and are available in various sizes and thicknesses to accommodate different load-bearing requirements.

Another type of metal angle bracket is the T-shaped bracket, which is used to join two perpendicular surfaces or provide additional support in structures. These brackets are also usually made from steel or aluminum and come in different sizes and strengths to suit different applications.

For heavier-duty applications, there are also U-shaped metal angle brackets, which are often used to support heavy loads or provide reinforcement in buildings or machinery. These brackets are typically made from thicker steel and are designed to withstand higher levels of stress and force.

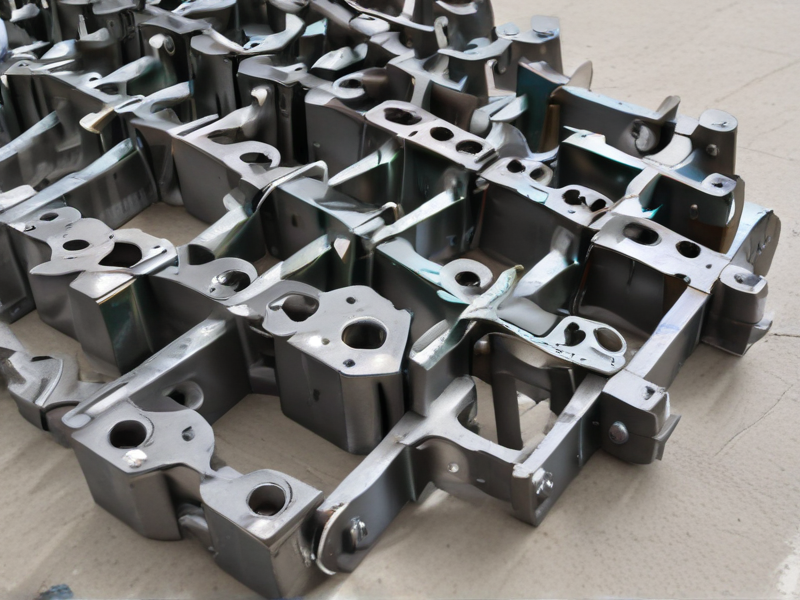

In addition to these common types of metal angle brackets, there are also specialized brackets available for specific applications, such as corner brackets, flat brackets, or adjustable brackets. These brackets may be made from stainless steel, galvanized steel, or other metals depending on the required strength and corrosion resistance.

Overall, metal angle brackets are essential components in construction and fabrication, providing structural support and stability in a wide range of applications. By choosing the right type of metal bracket for the job, you can ensure the safety and longevity of your structures.

Pros and Cons of Using angle brackets metal

Angle brackets made of metal offer several advantages over brackets made of other materials. Some of the pros include:

1. Strength and durability: Metal angle brackets are typically stronger and more durable than brackets made of plastic or other materials. This makes them ideal for applications where heavy loads need to be supported.

2. Corrosion resistance: Many metal angle brackets are made from materials such as stainless steel or galvanized steel, which are resistant to rust and corrosion. This makes them suitable for use in outdoor or high-moisture environments.

3. Aesthetic appeal: Metal angle brackets have a sleek and modern appearance, making them an attractive choice for both functional and decorative applications.

4. Versatility: Metal angle brackets can be used in a wide range of applications, from supporting shelves and countertops to reinforcing furniture or building structures.

Despite their many advantages, metal angle brackets also have some drawbacks. Some of the cons include:

1. Cost: Metal angle brackets are often more expensive than brackets made of other materials, such as plastic or wood. This can be a disadvantage for budget-conscious consumers or projects.

2. Weight: Metal angle brackets are typically heavier than brackets made of other materials, which can make them more difficult to install and may limit their use in certain applications.

3. Conductivity: Metal angle brackets can conduct heat and electricity, which may be a concern in certain applications where electrical insulation is needed.

In conclusion, metal angle brackets offer a range of advantages, including strength, durability, corrosion resistance, and aesthetic appeal. However, they may also be more expensive, heavier, and have conductivity issues compared to brackets made of other materials. Ultimately, the decision to use metal angle brackets will depend on the specific requirements of the project and the trade-offs that need to be considered.

angle brackets metal Reference Specifications (varies for different product)

Angle brackets are metal fasteners commonly used in carpentry and construction projects to reinforce joints and provide additional support. They are typically made of materials such as steel, aluminum, or stainless steel to ensure durability and strength.

The specifications for angle brackets can vary depending on the specific product and manufacturer. However, some common reference specifications include the size and dimensions of the bracket, the thickness of the metal used, and the weight capacity it can support. For example, a typical angle bracket may be 3 inches in length, 1 inch in width, and have a thickness of 1/8 inch.

It is important to choose the appropriate angle bracket for your project based on the specific requirements and load-bearing capacity needed. Some angle brackets may have a higher weight capacity than others, so it is essential to consult the manufacturer’s specifications before making a selection.

When installing angle brackets, it is important to use the appropriate hardware and follow the manufacturer’s guidelines for proper installation. This may include using screws or bolts that are the correct size and length for the bracket, as well as ensuring that the bracket is securely attached to the structure.

Overall, angle brackets are versatile and essential components in construction and carpentry projects, providing added reinforcement and support where needed. By following the reference specifications and guidelines provided by the manufacturer, you can ensure that your angle brackets are installed correctly and will effectively serve their intended purpose.

Applications of angle brackets metal

Angle brackets are commonly used in construction and fabrication projects due to their versatility and strength. One of the primary applications of angle brackets is to provide structural support and reinforcement for shelves, cabinets, furniture, and other similar items. They are often used to attach corners and joints securely, making them essential for ensuring the stability and longevity of various structures.

In addition to their use in construction, angle brackets are also frequently utilized in the automotive industry for mounting components, securing panels, and reinforcing frames. They can be found in vehicles of all types, from cars and trucks to motorcycles and bicycles, where they play a crucial role in ensuring the safety and reliability of the vehicle.

Angle brackets are also commonly used in industrial settings for mounting equipment, machinery, and piping systems. They provide a secure and stable mounting solution that is essential for the proper functioning of various industrial processes. Additionally, angle brackets are used in electrical and plumbing installations to support conduits, pipes, and fixtures, ensuring that they are securely fastened in place.

Overall, angle brackets are a versatile and essential component in a wide range of applications, from construction and fabrication to automotive and industrial engineering. Their strength, durability, and adaptability make them a valuable tool for professionals across various industries.

Material of angle brackets metal

Angle brackets are commonly used in construction and carpentry projects to provide additional support and reinforcement. They are typically made from metal, such as steel or aluminum, due to their durability and strength.

Metal angle brackets are available in a variety of sizes and designs to suit different applications. They are often used to connect two pieces of lumber at a 90-degree angle, providing stability and preventing the joint from bending or twisting under pressure.

One of the advantages of metal angle brackets is that they are easy to install with screws or nails, making them an ideal choice for DIY projects. They can also be used to secure shelves, cabinets, or other fixtures to walls or other surfaces.

In addition to their practical uses, metal angle brackets can also add a decorative touch to a project. They come in various finishes, such as black, silver, or gold, allowing them to complement the overall aesthetic of the design.

Overall, metal angle brackets are a versatile and reliable choice for providing additional support and reinforcement in a wide range of projects. Their durability, strength, and ease of installation make them a popular option for both professionals and DIY enthusiasts alike.

Quality Testing Methods for angle brackets metal and how to control the quality

There are several quality testing methods for angle brackets made of metal. One common method is visual inspection, where the brackets are checked for any visual defects such as cracks, dents, or other imperfections. Another method is dimensional inspection, where the dimensions of the brackets are measured to ensure they meet the required specifications.

Additionally, mechanical testing can be done to evaluate the strength and durability of the brackets. This can include tests such as tensile testing to measure the maximum load the brackets can withstand before breaking, or bending tests to assess their flexibility.

To control the quality of angle brackets, it is important to establish clear quality standards and specifications for the brackets. Regular inspections should be conducted throughout the manufacturing process to identify any defects or deviations from the standards. Any issues should be addressed promptly to prevent further production of defective brackets.

Furthermore, implementing a quality management system, such as ISO 9001, can help ensure consistency and adherence to quality standards. This system can help track and record quality control measures, as well as provide guidelines for continuous improvement.

Overall, by implementing thorough quality testing methods and maintaining strict quality control measures, manufacturers can produce high-quality angle brackets that meet the requirements of their customers.

The Work Process and how to use angle brackets metal

Using angle brackets in metalworking involves a few key steps to ensure a successful and professional outcome.

Firstly, it is important to select the appropriate size and material of angle bracket for your project. Angle brackets typically come in various sizes and materials such as steel, aluminum, or stainless steel. Choose the one that best suits your needs based on the weight and strength requirements of your project.

Next, position the angle brackets correctly on the metal surface where they will be attached. Using a metal square or ruler can help ensure that the brackets are properly aligned and square to the surface.

Once the angle brackets are in position, mark the locations of the screw or bolt holes on the metal surface using a pencil or marker. Ensure that the holes are evenly spaced and aligned with the holes in the angle brackets.

Drill the holes in the marked locations on the metal surface using a drill bit that is appropriate for the size of the screws or bolts you will be using to attach the angle brackets.

Finally, attach the angle brackets to the metal surface using the appropriate screws or bolts and a screwdriver or wrench. Make sure to tighten them securely to ensure a strong and stable connection.

In conclusion, using angle brackets in metalworking can be a straightforward process if done correctly. By following these steps and paying attention to detail, you can successfully incorporate angle brackets into your metal projects with ease.

angle brackets metal Importing questions including Cost,Supplier,Sample,Certification and Market

When importing metal products, there are several important questions to consider:

1. Cost: What is the cost of the metal products you are importing, including transportation fees, customs duties, and any other associated costs? It is essential to factor in all expenses to determine the overall cost and ensure it fits within your budget.

2. Supplier: Who is the supplier of the metal products? It is crucial to work with a reputable and reliable supplier to ensure the quality and timeliness of the products. Conduct thorough research and consider factors such as their experience, track record, and customer reviews before making a decision.

3. Sample: Can you request a sample of the metal products before making a bulk purchase? It is advisable to inspect the quality and specifications of the products firsthand to avoid any potential issues. Requesting a sample can help you make an informed decision and ensure that the products meet your requirements.

4. Certification: Does the metal products have the necessary certifications and compliance standards? It is important to ensure that the products meet all regulatory requirements and quality standards to avoid any legal or safety issues. Requesting documentation for certifications such as ISO, CE, or RoHS can help verify the quality and legitimacy of the products.

5. Market: What is the demand for metal products in your target market? Conduct market research to understand the trends, competition, and potential opportunities for metal products in your area. By analyzing the market, you can make informed decisions on factors such as pricing, marketing strategies, and sales channels to maximize your import business’s success.

How to find and select check reliable angle brackets metal manufacturers in China

When looking for reliable angle brackets metal manufacturers in China, it is important to carefully vet potential suppliers to ensure quality products and reliable service. Here are steps to help you find and select a reputable manufacturer:

1. Research and shortlist potential manufacturers: Start by researching online directories, trade shows, and industry associations to identify angle brackets metal manufacturers in China. Look for companies with a good reputation, experience in the industry, and a track record of producing high-quality products.

2. Verify credentials and certifications: Check if the manufacturers have the necessary certifications and credentials, such as ISO 9001 certification for quality management systems. This ensures that the company follows international quality standards and processes.

3. Request samples and product information: Ask for samples of their angle brackets metal products to assess the quality and craftsmanship. Also, inquire about their production process, materials used, and customization options.

4. Evaluate communication and response time: Ensure that the manufacturer is responsive to your inquiries and communicates effectively in English. This will be crucial for smooth collaboration and resolving any issues that may arise.

5. Check for references and reviews: Ask for references from past clients or check online reviews to get feedback on the manufacturer’s reputation, reliability, and customer service.

6. Negotiate terms and pricing: Lastly, discuss pricing, lead times, payment terms, and other important details before finalizing the partnership. Make sure to clarify any expectations and ensure that the manufacturer can meet your specific requirements.

By following these steps, you can find a reliable angle brackets metal manufacturer in China that meets your quality standards and production needs. Remember to prioritize quality, communication, and trust when selecting a manufacturer.

Background Research for angle brackets metal manufacturers Companies in China, use qcc.com archive.org importyeti.com

Angle brackets are commonly used in construction and industrial applications for providing structural support and reinforcement. In China, there are several manufacturers specializing in the production of metal angle brackets.

One such company is Shanghai Metal Corporation, which is a leading manufacturer and supplier of metal angle brackets in China. They offer a wide range of angle brackets in various sizes and materials, including stainless steel, aluminum, and carbon steel. Shanghai Metal Corporation is known for its high-quality products and reliable services, making them a trusted supplier in the industry.

Another prominent manufacturer of metal angle brackets in China is Shenzhen Launch Co., Ltd. They have a comprehensive range of angle brackets that are designed and manufactured to meet international quality standards. Shenzhen Launch Co., Ltd. is known for its innovative design solutions and efficient production processes, making them a preferred choice for customers worldwide.

Other notable manufacturers of metal angle brackets in China can be found on qcc.com, archive.org, and importyeti.com. These platforms provide valuable information on the companies’ product offerings, manufacturing capabilities, and customer reviews. By utilizing these resources, businesses can identify the most suitable manufacturer for their specific requirements and ensure high-quality products at competitive prices.

Price Cost Research for angle brackets metal manufacturers Companies in China, use temu.com and 1688.com

When researching angle brackets metal manufacturers in China, two popular platforms to use are temu.com and 1688.com. These websites offer a wide range of suppliers and products, making it easy to find the best price for angle brackets.

To begin your search, simply enter “angle brackets metal manufacturers” in the search bar on temu.com and 1688.com. You will find a list of suppliers offering angle brackets at competitive prices.

When comparing prices, it is important to consider factors such as the quality of the product, the minimum order quantity, and shipping costs. Some suppliers may offer discounts for bulk orders, so be sure to inquire about pricing for different quantities.

In addition to comparing prices, it is also important to research the reputation of the suppliers. Look for reviews from other buyers, and consider reaching out to the suppliers directly to ask any questions you may have.

By using temu.com and 1688.com, you can easily find angle brackets metal manufacturers in China and compare prices to ensure you are getting the best deal for your needs.

Shipping Cost for angle brackets metal import from China

The shipping cost for importing angle brackets metal from China can vary depending on several factors. These factors include the weight and dimensions of the shipment, the shipping method chosen, and the shipping company used.

When shipping angle brackets metal from China, it is important to consider whether you will be using air, sea, or courier services. Air freight is typically the fastest but also the most expensive option, especially for larger or heavier shipments. Sea freight is usually more cost-effective for larger shipments, but it can take longer for the goods to arrive.

Courier services such as DHL, FedEx, or UPS may be a good option for smaller shipments of angle brackets metal. These services are typically faster than sea freight and may offer competitive rates for smaller packages.

It is also important to consider any additional charges that may apply, such as customs duties, taxes, or handling fees. These costs can vary depending on the country of import and the value of the shipment.

To get an accurate estimate of the shipping cost for importing angle brackets metal from China, it is recommended to contact several shipping companies for quotes. Provide them with detailed information about the shipment, including the weight, dimensions, and shipping method, to ensure the most accurate pricing.

Overall, it is important to carefully consider all factors when calculating the shipping cost for importing angle brackets metal from China to ensure a smooth and cost-effective import process.

Compare China and Other angle brackets metal Markets: Products Quality and Price,Visible and Hidden Costs

When comparing China and other angle brackets metal markets, there are several factors to consider, including products quality and price, visible and hidden costs.

In terms of products quality, China is known for producing a wide range of metal products, including angle brackets, at varying levels of quality. While some Chinese manufacturers offer high-quality products that meet international standards, others may produce lower-quality items that do not meet the same standards. On the other hand, other metal markets may have a reputation for producing consistently high-quality items but at a higher price point.

Price is another important factor to consider when comparing these markets. China is often able to offer competitive prices on metal products due to lower labor and production costs. This can make Chinese products more appealing to budget-conscious buyers. However, the lower price point may come with trade-offs in terms of product quality, reliability, and customer service compared to other markets.

Visible costs, such as the initial purchase price of the products, are straightforward to compare between China and other markets. However, hidden costs, such as shipping, import duties, and quality control issues, may vary depending on the market. These hidden costs can quickly add up and impact the overall cost-effectiveness of purchasing from one market over another.

In conclusion, when comparing China and other metal markets for angle brackets, it is essential to consider factors such as product quality, price, visible and hidden costs. Each market has its strengths and weaknesses, and buyers should carefully evaluate these factors to make an informed decision on where to source angle brackets for their needs.

Custom Private Labeling and Branding Opportunities with Chinese angle brackets metal Manufacturers

Chinese angle brackets metal manufacturers offer a range of custom private labeling and branding opportunities for businesses looking to enhance their product offerings. With their expertise in metal fabrication and extensive experience in manufacturing, these manufacturers can help you create unique and high-quality angle brackets that meet your specific requirements.

By partnering with a Chinese angle brackets metal manufacturer, you can take advantage of their state-of-the-art facilities and skilled workforce to customize your products with your own branding and logo. Whether you want to add a logo, company name, or other branding elements to your angle brackets, these manufacturers can accommodate your needs and ensure that your products stand out in the market.

Additionally, Chinese manufacturers can provide packaging and labeling services to help you create a cohesive and professional look for your products. By working closely with their design team, you can develop packaging that reflects your brand identity and effectively showcases your angle brackets to customers.

Overall, partnering with a Chinese angle brackets metal manufacturer for custom private labeling and branding opportunities can help you differentiate your products, increase brand recognition, and attract more customers. With their expertise and resources, you can create customized angle brackets that meet your exact specifications and elevate your brand in the market.

Tips for Procurement and Considerations when Purchasing angle brackets metal

When purchasing angle brackets metal, here are some important tips and considerations to keep in mind:

1. Material: Make sure to choose angle brackets made from high-quality metal such as stainless steel or galvanized steel to ensure durability and strength.

2. Size and Thickness: Consider the size and thickness of the angle brackets based on the weight and size of the items you will be supporting. Thicker brackets are generally stronger and more durable.

3. Coating: Look for angle brackets with a protective coating such as powder coating or zinc plating to prevent corrosion and rusting, especially if they will be used outdoors or in damp environments.

4. Load Capacity: Check the load capacity of the angle brackets to ensure they can safely support the weight of the items they will be holding.

5. Design: Consider the design of the angle brackets, including the number of holes for screws or bolts and the angle of the bracket, to ensure they will fit and function properly for your specific application.

6. Quantity: Determine the quantity of angle brackets needed for your project or application to ensure you have enough brackets to securely support the items.

7. Cost: Compare prices from different suppliers to find the best quality angle brackets at a competitive price that fits within your budget.

By keeping these tips and considerations in mind, you can ensure that you are purchasing the right angle brackets metal for your specific needs and that they will provide reliable support for your items.

FAQs on Sourcing and Manufacturing angle brackets metal in China

1. Where can I source metal angle brackets in China?

You can source metal angle brackets in China through various sourcing platforms, such as Alibaba, Made-in-China, and Global Sources. You can also attend trade shows, like the Canton Fair, to connect with manufacturers directly.

2. How do I find a reliable manufacturer for metal angle brackets in China?

To find a reliable manufacturer, conduct thorough research by checking their company profiles, reviews, and certifications. It is also advisable to visit their factory to ensure they meet your quality standards.

3. What materials can be used for manufacturing metal angle brackets in China?

Common materials used for manufacturing metal angle brackets in China include stainless steel, aluminum, and carbon steel. Depending on your specific requirements, the manufacturer can also customize the material to meet your needs.

4. How long does it take to manufacture metal angle brackets in China?

The manufacturing lead time for metal angle brackets in China can vary depending on the complexity of the design, quantity ordered, and the manufacturer’s production capacity. It is advisable to confirm the lead time with the manufacturer before placing an order.

5. Are there any quality control measures in place for manufacturing metal angle brackets in China?

Yes, reputable manufacturers in China have strict quality control measures in place to ensure the products meet international standards. This includes inspections throughout the production process and final inspections before shipment.

6. Can I customize the design of metal angle brackets with Chinese manufacturers?

Yes, most Chinese manufacturers offer customization services for metal angle brackets. You can work with their design team to create a product that meets your specific requirements and specifications.

Why contact sourcifychina.com get free quota from reliable angle brackets metal suppliers?

Sourcifychina.com offers a valuable service in connecting businesses with reliable angle brackets metal suppliers in China. By contacting Sourcifychina.com, businesses can easily request a free quota from these suppliers, saving time and resources in the sourcing process.

The benefits of using Sourcifychina.com to connect with reliable angle brackets metal suppliers include access to a wide network of trusted manufacturers, ensuring quality products at competitive prices. Additionally, Sourcifychina.com can assist businesses in negotiating pricing and terms with suppliers, ensuring a smooth and successful transaction.

By requesting a free quota from Sourcifychina.com’s network of suppliers, businesses can compare offers and make informed decisions based on their specific needs and budget. This eliminates the hassle of individually contacting multiple suppliers and streamlines the sourcing process.

Overall, contacting Sourcifychina.com for a free quota from reliable angle brackets metal suppliers is a smart business decision that can save time, reduce costs, and ensure the quality of products sourced from China.