Top fabrication of aluminum in China introduce,list main products and website if have

China is one of the leading countries in the fabrication of aluminum products, with numerous companies specializing in the production of various aluminum products. Some of the top fabrication companies in China include:

1. Nanhai Huayang Aluminum Products Co., Ltd. – This company specializes in the fabrication of aluminum extrusions, aluminum profiles, and aluminum windows and doors. Their website is: http://www.huayang-alu.com/

2. Zhongwang Group – Zhongwang is a leading manufacturer of industrial aluminum extrusions and aluminum products for various industries. Their website is: http://www.zhongwang.com/

3. ByTune Electronics Co., Ltd. – ByTune Electronics is a professional CNC machining and die casting company that specializes in aluminum fabrication. Their website is: http://www.btcncmachining.com/

4. Guangdong JMA Aluminium Profile Factory (Group) Co., Ltd. – JMA Aluminum is a leading manufacturer of aluminum extrusions, aluminum profiles, and aluminum windows and doors. Their website is: http://www.jma-aluminum.com/

5. Jiangsu Kailun Aluminum Co., Ltd. – Kailun Aluminum is a professional manufacturer of aluminum coils, aluminum sheets, and aluminum foil products. Their website is: http://www.kailunaluminum.com/

These companies offer a wide range of aluminum products, including extrusions, profiles, windows and doors, coils, sheets, and foil, catering to various industries such as construction, automotive, electronics, and packaging. With advanced manufacturing facilities and high-quality standards, Chinese aluminum fabrication companies are trusted by customers worldwide for their reliable and efficient production capabilities.

Types of fabrication of aluminum

Aluminum fabrication is the process of shaping, cutting, and assembling aluminum materials into finished products. There are several methods of fabrication that are commonly used to manipulate aluminum into desired shapes and structures:

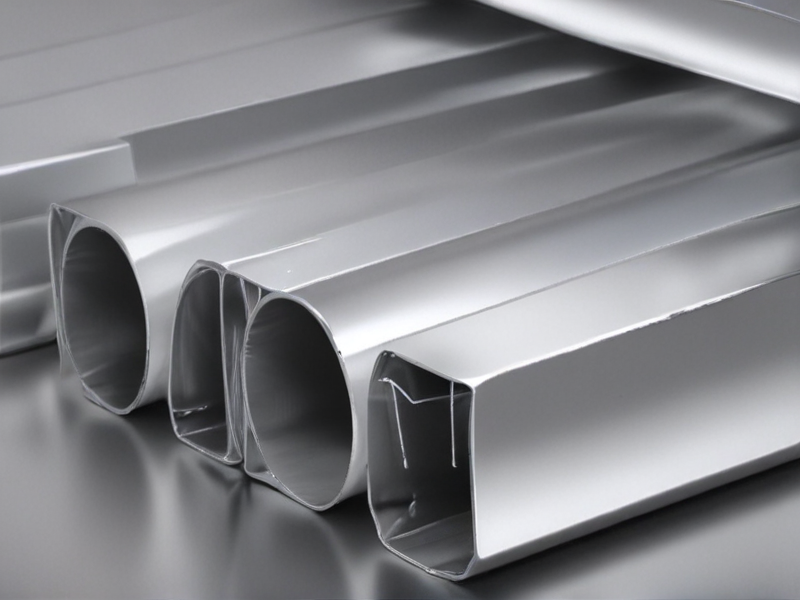

1. Extrusion: Extrusion is a process in which a billet of aluminum is forced through a die to create a specific cross-sectional shape. This method is commonly used for creating aluminum bars, rods, and tubes with consistent cross-sections.

2. Casting: Casting involves pouring molten aluminum into a mold to create complex shapes and designs. This method is often used for creating intricate aluminum parts and components.

3. Machining: Machining is a process in which aluminum is cut, drilled, and shaped using various cutting tools and machinery. This method is commonly used for creating precision parts and components with tight tolerances.

4. Welding: Welding is a process in which two pieces of aluminum are joined together by melting the surfaces and fusing them together. This method is commonly used for joining aluminum parts and components in various industries.

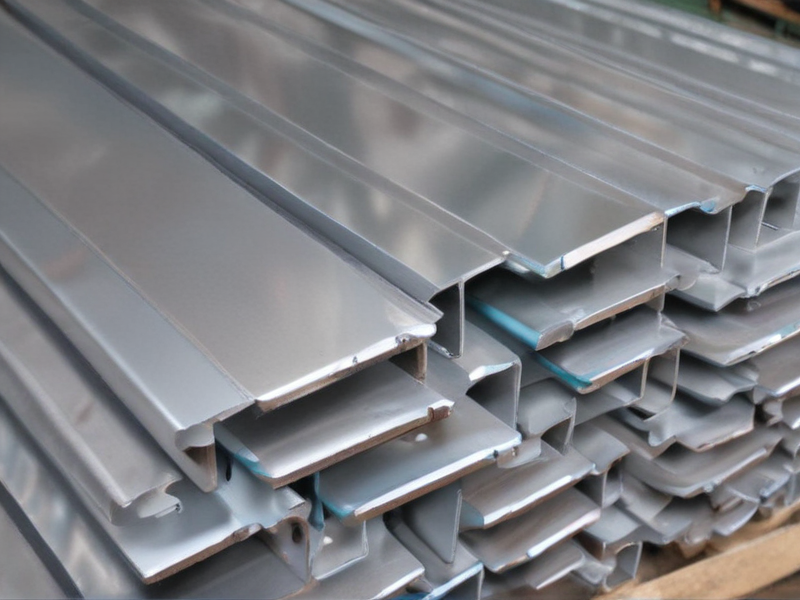

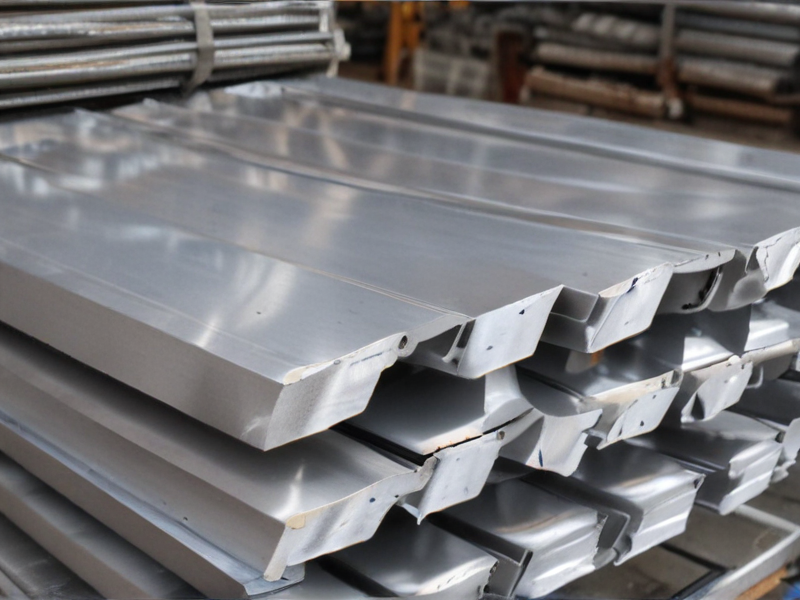

5. Forming: Forming involves bending, stamping, and shaping aluminum sheets and plates into desired shapes and structures. This method is commonly used for creating aluminum panels, enclosures, and other structural components.

Overall, aluminum fabrication involves a combination of these methods to produce a wide range of products and components that are used in various industries such as aerospace, automotive, construction, and electronics. Each method of fabrication has its own advantages and limitations, and the choice of method depends on the specific requirements of the project.

Pros and Cons of Using fabrication of aluminum

One of the major advantages of using aluminum for fabrication is its lightweight nature. Aluminum is significantly lighter than other metals such as steel, making it easier to transport and manipulate during the fabrication process. Additionally, aluminum is a relatively malleable material, allowing for easy shaping and forming into various designs and structures.

Another advantage of using aluminum for fabrication is its high strength-to-weight ratio. Despite its lightweight nature, aluminum is a durable metal that offers good structural stability and resistance to corrosion. This makes it an ideal choice for a wide range of applications, including automotive, aerospace, and construction.

Furthermore, aluminum is a highly recyclable material, making it a sustainable option for fabrication. Recycling aluminum requires only a fraction of the energy needed to produce new aluminum, making it an environmentally friendly choice for manufacturers and consumers.

However, there are also some disadvantages of using aluminum for fabrication. One drawback is that aluminum can be more expensive than other metals such as steel or iron. The cost of aluminum fabrication may be higher due to the energy-intensive process of extracting and refining the metal.

Additionally, aluminum is not as strong or durable as steel in certain applications. While aluminum offers good corrosion resistance, it may not be suitable for high-stress applications that require the strength and toughness of steel.

In conclusion, the use of aluminum for fabrication offers numerous advantages, including its lightweight nature, high strength-to-weight ratio, and recyclability. However, the higher cost and limitations in strength compared to steel are important factors to consider when deciding whether to use aluminum for fabrication.

fabrication of aluminum Reference Specifications (varies for different product)

Aluminum fabrication refers to the manufacturing process of shaping, cutting, and forming aluminum into various products. The specifications for aluminum fabrication vary depending on the specific product being produced. Some common reference specifications for aluminum fabrication include ASTM B209 for aluminum and aluminum-alloy sheet and plate, ASTM B211 for aluminum and aluminum-alloy bar, rod, and wire, and ASTM B221 for aluminum and aluminum-alloy extruded bars, rods, wire, shapes, and tubes.

In aluminum fabrication, the material is typically cut and shaped using processes such as cutting, bending, welding, and machining. Aluminum is known for its lightweight, corrosion-resistant properties, making it a popular choice for a wide range of applications including automotive parts, building materials, and electronic components.

Aluminum fabrication processes must adhere to strict quality standards to ensure the final product meets the required specifications. This may include testing the material for strength, durability, and chemical composition. Additionally, surface finishing such as painting, anodizing, or powder coating may be applied to improve the aesthetic appeal and protect the aluminum from environmental factors.

Overall, aluminum fabrication requires precision, expertise, and attention to detail to produce high-quality products that meet the specific requirements of the customer. By following reference specifications and utilizing advanced fabrication techniques, manufacturers can ensure the successful production of aluminum products for various industries.

Applications of fabrication of aluminum

Aluminum fabrication is a process that involves shaping and molding aluminum into various forms for a wide range of applications. Some common uses of fabricated aluminum include:

1. Aerospace: Aluminum is commonly used in the aerospace industry for its lightweight properties and strength. Fabricated aluminum components are used in aircraft structures, interior components, and engine parts.

2. Automotive: Aluminum is also used in the automotive industry for its lightweight properties and durability. Fabricated aluminum parts are used in car bodies, engine parts, wheels, and other components to reduce weight and improve fuel efficiency.

3. Construction: Fabricated aluminum is used in the construction industry for its corrosion resistance and strength. Aluminum components are used in building facades, window frames, roofing, and structural elements.

4. Electronics: Aluminum is used in the electronics industry for its conductivity and thermal properties. Fabricated aluminum enclosures and heat sinks are used in electronic devices to dissipate heat and protect sensitive components.

5. Packaging: Aluminum is commonly used in the packaging industry for its lightweight and recyclable properties. Fabricated aluminum packaging materials such as cans, foils, and pouches are used for food and beverage packaging.

6. Furniture: Aluminum is a popular choice for furniture design due to its lightweight, modern appearance, and corrosion resistance. Fabricated aluminum is used in chairs, tables, shelving, and other furniture pieces.

Overall, the fabrication of aluminum offers versatility and durability for a wide range of industries and applications. Its lightweight properties, corrosion resistance, and recyclability make it a valuable material for various projects.

Material of fabrication of aluminum

Aluminum is a versatile metal that is commonly used in a variety of applications due to its lightweight and corrosion-resistant properties. It is a silvery-white, soft, non-magnetic metal that is the third most abundant element in the Earth’s crust, making up about 8% of the Earth’s solid surface.

The process of extracting aluminum from its ore, known as bauxite, involves a series of chemical reactions that require a significant amount of energy. Once the aluminum is extracted, it can be fabricated into various forms through processes such as casting, extrusion, and rolling.

Aluminum is commonly alloyed with other metals to enhance its properties. One of the most common alloys is aluminum 6061, which contains magnesium and silicon to improve its strength and weldability. Other popular alloys include aluminum 7075, which is known for its high strength and fatigue resistance, and aluminum 5052, which is often used for its corrosion resistance.

Aluminum is widely used in industries such as aerospace, automotive, construction, and packaging. It is commonly found in products such as airplane parts, car bodies, window frames, and beverage cans. Aluminum is also commonly used in electrical transmission lines and as a heat sink in electronic devices.

Overall, aluminum is a valuable material of fabrication due to its abundance, low density, and high strength-to-weight ratio. Its versatility and recyclability make it an attractive choice for a wide range of applications across various industries.

Quality Testing Methods for fabrication of aluminum and how to control the quality

There are several quality testing methods that can be used during the fabrication of aluminum to ensure that the final product meets the desired specifications. Some common methods include:

1. Visual inspection: This involves visually examining the aluminum for any defects such as cracks, dents, or surface imperfections.

2. Dimensional inspection: This involves measuring the dimensions of the aluminum using tools such as calipers or micrometers to ensure that it meets the required specifications.

3. Tensile testing: This test evaluates the strength of the aluminum by applying tensile force to a sample until it reaches its breaking point. This helps determine the material’s durability and ability to withstand stress.

4. Hardness testing: This test measures the hardness of the aluminum using materials such as Rockwell or Brinell hardness testers. This helps assess the metal’s resistance to deformation and wear.

To control the quality of aluminum fabrication, it is important to implement a quality management system that includes regular inspections, testing, and documentation of results. This system should include procedures for identifying and addressing any defects or deviations from specifications. Additionally, it is crucial to train personnel on quality control measures and provide the necessary tools and equipment for testing and inspection.

Overall, by implementing stringent quality testing methods and maintaining a strong quality management system, manufacturers can ensure that the fabricated aluminum meets the desired specifications and is of high quality. This not only enhances the reputation of the manufacturer but also ensures the safety and reliability of the final product.

The Work Process and how to use fabrication of aluminum

The fabrication of aluminum involves a series of processes to transform raw aluminum material into a finished product. The work process begins by selecting the appropriate grade and thickness of aluminum for the desired application. Once the material is chosen, it is cut to size using specialized equipment such as saws or CNC machines.

Next, the aluminum is shaped or formed using techniques such as bending, stamping, or rolling to achieve the desired dimensions and geometry. This may involve using tools such as presses, rollers, or dies to manipulate the material into the required shape.

After shaping, the aluminum may be assembled with other components using methods such as welding, riveting, or bonding. This step is crucial in creating a strong and durable final product.

Once the fabrication process is complete, the aluminum may undergo surface treatments such as painting, anodizing, or powder coating to enhance its appearance and improve its corrosion resistance.

In conclusion, the fabrication of aluminum involves a combination of cutting, shaping, assembling, and finishing processes to transform raw material into a functional and aesthetically pleasing product. Attention to detail and precision are key in ensuring the quality and performance of the final product.

fabrication of aluminum Importing questions including Cost,Supplier,Sample,Certification and Market

Cost: What is the cost of importing aluminum fabrication products? Are there any additional fees or charges that need to be taken into consideration?

Supplier: Can you provide information on potential suppliers for aluminum fabrication products? What are their qualifications and experience in the industry?

Sample: Is it possible to request a sample of the aluminum fabrication products before placing a bulk order? What is the process for obtaining a sample?

Certification: Are the aluminum fabrication products certified by any relevant industry standards or certifications? What quality control measures are in place to ensure the products meet the required standards?

Market: What is the demand for aluminum fabrication products in the market? Are there any specific trends or developments that could affect the importation of these products?

In summary, when considering the importation of aluminum fabrication products, it is important to inquire about the cost, potential suppliers, the availability of samples, certification of products, and the current market demand. This information will help in making informed decisions and ensuring the successful importation of high-quality aluminum fabrication products.

How to find and select check reliable fabrication of aluminum manufacturers in China

When looking for reliable aluminum fabrication manufacturers in China, there are a few key steps you can take to ensure you make the right choice.

First, start by doing thorough research online. Look for manufacturers with a good reputation and experience in the industry. You can also check reviews and testimonials from previous customers to get an idea of their reliability and quality of work.

Next, make sure the manufacturer has the necessary certifications and qualifications to fabricate aluminum products. This includes certifications such as ISO 9001 or other industry-specific accreditations.

It is also important to visit the manufacturing facility if possible to see their processes firsthand and ensure they have the capabilities to meet your specific requirements.

Obtain quotes from multiple manufacturers to compare pricing, lead times, and quality of work. Keep in mind that the cheapest option may not always be the best in terms of quality and reliability.

Lastly, communicate openly with the manufacturer and ask questions about their processes, materials, and quality control measures. A reliable manufacturer will be transparent and responsive to your inquiries.

By following these steps, you can select a reliable aluminum fabrication manufacturer in China that meets your needs and ensures a successful partnership.

Background Research for fabrication of aluminum manufacturers Companies in China, use qcc.com archive.org importyeti.com

China is one of the largest producers of aluminum in the world, with a significant number of companies specializing in the fabrication of aluminum products. One of the most well-known companies in this sector is Aluminum Corporation of China (Chalco), which is a state-owned enterprise and one of the largest aluminum producers in the world.

Other prominent companies in the fabrication of aluminum in China include China Hongqiao Group, which is one of the largest aluminum producers in China, and Aluminum Corporation of China Limited (ACH). These companies have a strong presence in both the domestic and international markets, with a wide range of products including aluminum sheets, coils, and extrusions.

The fabrication process of aluminum involves melting aluminum ingots and casting them into various shapes and forms. This process requires advanced technology and equipment to ensure high-quality products. Chinese companies in this sector often invest heavily in research and development to improve their processes and develop new products.

In recent years, there has been a growing trend towards environmentally friendly practices in the aluminum fabrication industry in China. Companies are increasingly adopting sustainable production methods and investing in energy-efficient technologies to reduce their carbon footprint.

Overall, the fabrication of aluminum in China is a highly competitive industry, with a large number of companies vying for market share both domestically and internationally. By utilizing resources such as qcc.com, archive.org, and importyeti.com, companies can stay informed about market trends, competitors, and regulations to stay ahead in this dynamic industry.

Price Cost Research for fabrication of aluminum manufacturers Companies in China, use temu.com and 1688.com

When conducting price cost research for fabrication of aluminum manufacturers in China, two popular websites to use are temu.com and 1688.com. These websites provide a wide range of suppliers and manufacturers, allowing you to compare prices and costs for aluminum fabrication services.

On temu.com, you can search for specific aluminum manufacturers and request quotes directly from suppliers. You can also filter your search based on location, certifications, and other criteria to find the most suitable options for your fabrication needs. Additionally, temu.com provides information on company profiles, product offerings, and customer reviews to help you make informed decisions.

1688.com, on the other hand, is a popular online marketplace in China that offers a wide range of products and services, including aluminum fabrication. You can search for suppliers, compare prices, and read reviews from other buyers to assess the quality and reliability of each manufacturer. 1688.com also allows you to contact suppliers directly to negotiate prices and discuss your specific requirements.

By using these two platforms for price cost research, you can find competitive quotes for aluminum fabrication services in China. It is important to consider factors such as quality, lead times, and shipping costs when making your decision to ensure a successful partnership with the chosen manufacturer.

Shipping Cost for fabrication of aluminum import from China

The shipping cost for the fabrication of aluminum imported from China will depend on a variety of factors, such as the volume of material being imported, the distance it needs to travel, and the method of transportation chosen.

Typically, the cost of shipping aluminum from China to the United States ranges from $1 to $3 per kilogram. This cost may vary based on the size and weight of the shipment, as well as the chosen shipping method.

Air freight is typically the fastest but most expensive option, with rates starting at around $3 per kilogram. Sea freight is a more cost-effective solution, with rates starting at around $1 per kilogram. However, sea freight takes longer to transport the goods, which may impact production timelines.

It’s important to consider additional costs such as customs duties, taxes, and insurance when calculating the total shipping cost. Some suppliers may offer CIF (Cost, Insurance, and Freight) pricing, which includes shipping costs, insurance, and freight charges, while others may offer FOB (Free on Board) pricing, which only includes shipping costs.

To ensure the most cost-effective shipping solution, it’s recommended to compare rates from different shipping companies and explore different transportation methods. Additionally, working with a reliable freight forwarder or logistics provider can help streamline the shipping process and minimize costs.

Compare China and Other fabrication of aluminum Markets: Products Quality and Price,Visible and Hidden Costs

China is one of the world’s largest producers of fabricated aluminum products, offering a wide range of products in terms of quality and price. The quality of Chinese aluminum products can vary significantly depending on the manufacturer, with some companies producing high-quality products that meet international standards, while others may offer lower quality products at cheaper prices.

In comparison, other fabrication markets such as the United States or Europe generally have higher standards for product quality and may offer more consistent quality across manufacturers. However, this often comes at a higher price, as labor and production costs are generally higher in these regions.

In terms of visible costs, Chinese aluminum products are often priced lower than products from other markets, making them more attractive to buyers looking for cost-effective solutions. However, hidden costs such as transportation, import duties, and potential quality issues may need to be taken into consideration when purchasing Chinese products.

On the other hand, products from other markets may have higher upfront costs, but may offer better quality and reliability, potentially reducing hidden costs in the long run. Buyers must weigh these factors when making purchasing decisions, taking into account their specific needs for quality, price, and reliability.

Overall, China and other fabrication markets offer a range of aluminum products with varying quality and price points. Buyers must carefully consider their priorities and weigh the visible and hidden costs associated with each option to make the best choice for their specific requirements.

Custom Private Labeling and Branding Opportunities with Chinese fabrication of aluminum Manufacturers

Chinese fabrication of aluminum manufacturers offer custom private labeling and branding opportunities for businesses looking to create their own personalized products. By working with these manufacturers, companies can have their logos, colors, and designs applied to aluminum products such as containers, packaging, and furniture.

This customization allows businesses to differentiate themselves in the market and create a unique brand identity. It also helps companies to establish brand recognition and loyalty among customers. Additionally, custom private labeling and branding can help businesses to increase their competitive advantage and boost sales.

Working with Chinese fabrication of aluminum manufacturers also offers cost-effective solutions for businesses looking to produce high-quality, customized products. The manufacturers have the expertise and experience in producing aluminum products to meet various specifications and requirements.

With the growing demand for personalized products, businesses can take advantage of the opportunities provided by Chinese fabrication of aluminum manufacturers to create unique, branded products that stand out in the market. By working closely with these manufacturers, businesses can turn their branding ideas into reality and achieve their marketing goals.

Overall, collaborating with Chinese fabrication of aluminum manufacturers for custom private labeling and branding opportunities can help businesses to create a strong brand identity, increase market visibility, and drive sales growth. Businesses looking to stand out in a competitive market should consider exploring these opportunities with Chinese manufacturers.

Tips for Procurement and Considerations when Purchasing fabrication of aluminum

1. Define your project requirements: Before purchasing the fabrication of aluminum, clearly define your project requirements including the desired dimensions, quality standards, budget constraints, and timeline. This will help you to communicate your needs effectively to potential suppliers.

2. Research potential suppliers: Conduct thorough research to identify potential suppliers who have the capability and experience in fabricating aluminum. Look for suppliers who have a track record of delivering high-quality products on time and within budget.

3. Request quotes: Reach out to multiple suppliers to request quotes for the fabrication of aluminum. Compare the quotes based on price, quality, lead time, and other factors to make an informed decision.

4. Quality assurance: Ensure that the supplier you choose follows quality assurance processes to guarantee the quality of the fabricated aluminum. Ask for certifications or references to verify the supplier’s quality standards.

5. Communication and collaboration: Maintain open communication with the supplier throughout the fabrication process to address any issues or changes that may arise. Collaborate closely to ensure that the final product meets your expectations.

6. Consider sustainability: In addition to quality and price, consider the sustainability practices of the supplier in terms of environmental impact, ethical labor practices, and waste management. Choose a supplier that aligns with your values and sustainability goals.

7. Delivery and logistics: Consider the logistics of transporting the fabricated aluminum to your location. Make sure to discuss delivery options, lead times, and any additional costs associated with shipping.

By following these tips and considerations, you can ensure a successful procurement process when purchasing the fabrication of aluminum.

FAQs on Sourcing and Manufacturing fabrication of aluminum in China

Q: Why should I consider sourcing fabrication of aluminum in China?

A: China has a well-established aluminum industry with competitive pricing, advanced technology, and a wide range of capabilities to meet your fabrication requirements.

Q: How do I find reliable manufacturers in China for aluminum fabrication?

A: You can start by researching online directories, attending trade shows, or asking for recommendations from other companies. It is important to perform background checks, visit facilities, and ask for samples to ensure quality and reliability.

Q: What are the common fabrication processes offered by Chinese manufacturers for aluminum?

A: Chinese manufacturers typically offer a wide range of fabrication processes for aluminum, including cutting, bending, welding, CNC machining, anodizing, and powder coating.

Q: How can I ensure quality control in the manufacturing process?

A: Work closely with the manufacturer to define specifications, conduct regular inspections during production, and ask for test reports and certifications to ensure quality control throughout the manufacturing process.

Q: How can I manage language barriers and cultural differences when working with Chinese manufacturers?

A: Hiring a local agent or translator, communicating clearly and effectively, and building strong relationships with your Chinese counterparts can help mitigate language barriers and cultural differences during the sourcing and manufacturing process.

Why contact sourcifychina.com get free quota from reliable fabrication of aluminum suppliers?

Sourcifychina.com is a trusted platform that connects businesses with reliable aluminum suppliers in China. By contacting Sourcifychina.com, you can easily get a free quota for fabrication services from reputable suppliers.

Aluminum fabrication is a complex process that requires attention to detail and precision. By working with reliable suppliers through Sourcifychina.com, you can ensure that your products are fabricated to the highest standards. These suppliers have proven track records of delivering quality products on time and within budget.

Getting a free quota from reputable suppliers through Sourcifychina.com allows you to compare prices and services to find the best fit for your project. This can help you save time and money by ensuring that you are getting the best value for your investment.

Overall, contacting Sourcifychina.com for a free quota from reliable aluminum suppliers is a smart business move. It can help you streamline the fabrication process and ensure that your products meet the highest quality standards. Don’t miss out on this opportunity to connect with top-notch suppliers in China.